Arc flash protection standards

Understanding the NFPA standard for arc flash protection

The National Fire Protection Association (NFPA) develops and publishes more than 300 consensus codes and standards intended to eliminate death, injury, property and economic loss due to fire, electrical, and related hazards.

NFPA 70E

Edition 2012

Purpose:

The purpose of this standard is to provide a practical safe working area for employees relative to the hazards arising from the use of electricity.

Scope:

NFPA 70E addresses electrical safety-related work practices for employee workplaces that are necessary for the practical safeguarding of employees relative to the hazards associated with electrical energy during activities such as the installation, inspection, operation, maintenance and demolition of electric conductors, electric equipment, signaling and communications conductors and equipment, and raceways. This standard also includes safe work practices for employees performing other work activities that can expose them to electrical hazards, as well as safe work practices for the following:

1. Installation of conductors and equipment that connect to the supply of electricity

2. Installations used by the electric utility, such as office buildings, warehouses, garages, machine shops and recreational buildings that are not an integral part of a generating plant, substation or control center

Frequently Asked Questions

-

What is NFPA 70E and why is compliance to this standard so important?

Injury from electric shock and arc flash hazards is the sixth leading cause of occupational fatality in the U.S. On average, approximately 2,000 workers each year are admitted for hospital treatment due to electrical burns. The National Fire Protection Association (NFPA) 70E Standard is a comprehensive standard that provides detailed guidance instructions on administrative measures for controlling electrical shock and arc flash hazards in the workplace. It details how to protect workers from the heat of electric arc exposures.

-

What administrative controls are covered under NFPA 70E?

The administrative controls addressed include task planning, permitting for working on or near energized circuits, worker training, safe work practices and use of personal protective equipment (PPE).

-

What hazard control measures are not covered under NFPA 70E?

The standard does not address application of engineering design solutions to control exposures to electrical hazards. Engineering design solutions include substitution of less-hazardous equipment or systems and engineering controls that automatically prevent or limit exposure to hazardous energy. Examples of substitution include use of 24V control voltage vs. 120V or 480V control to limit shock energy and use of current limiting protective devices to limit arc flash energy vs. non-current limiting devices. Examples of engineering controls include use of GFCIs for limiting shock energy and use of arc-resistant switchgear, high-resistance grounding and zone-selective interlocking to limit exposure to arc energy.

-

Are electric utilities covered under NFPA 70E?

NFPA 70E does not address safe work practices specific to installation, maintenance and operation of utility transmission and distribution systems. There are some facilities and installations under utility control in which application of NFPA 70E may be appropriate. Examples include office buildings, warehouses, garages and maintenance shops.

-

As an employer, how can I protect my workers from electric arc threats?

Identify potential arc hazards in the workplace. Confirm the potential and assess the severity of arc hazards by performing an arc hazard analysis. Apply engineering solutions to reduce frequency and severity of exposure. Train workers on safe work practices. Provide PPE as required in NFPA 70E.

-

As a worker with potential exposure to arc hazards, how can I protect myself from electric arc threats?

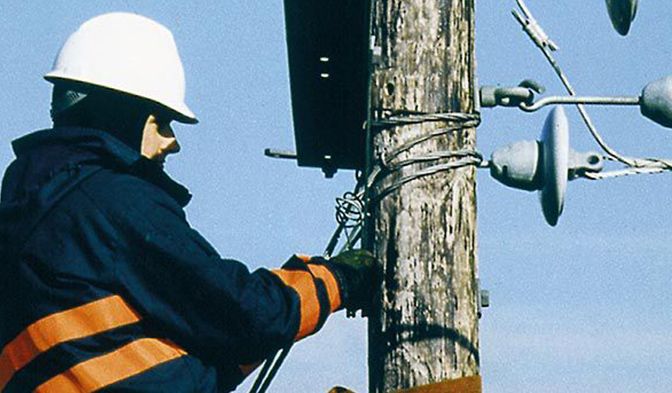

Seek training in the nature of arc hazards and the safe work practices outlined in NFPA 70E. Help protect yourself from electric arc exposures by wearing flame-resistant (FR) protective apparel whenever you’re on the job site.